Yoshimi Kato SG2 Minamo Nakiri 165mm

Yoshimi Kato SG2 Minamo Nakiri 165mm

Couldn't load pickup availability

About Yoshimi Kato - Second careers are often the best. I know of a burned-out chef, for example, who owns a few knife shops now. Then there's Yoshimi Kato, who left his job as the project manager of a construction company to become a blacksmith after marrying Hiroshi Kato's daughter.

Normally, it takes apprentices some 10 – 15 years to become pros, but Kato-san did it in just 5 years, and is now running the show. He forges most of the Masakage Kiri, Yuki, and Koishi knives that were once his father-in-law's domain. Kato-san also brings a very special level of professionalism and care to his customers’ orders, ensuring that each and every finished blade fully meets his exacting quality standards.

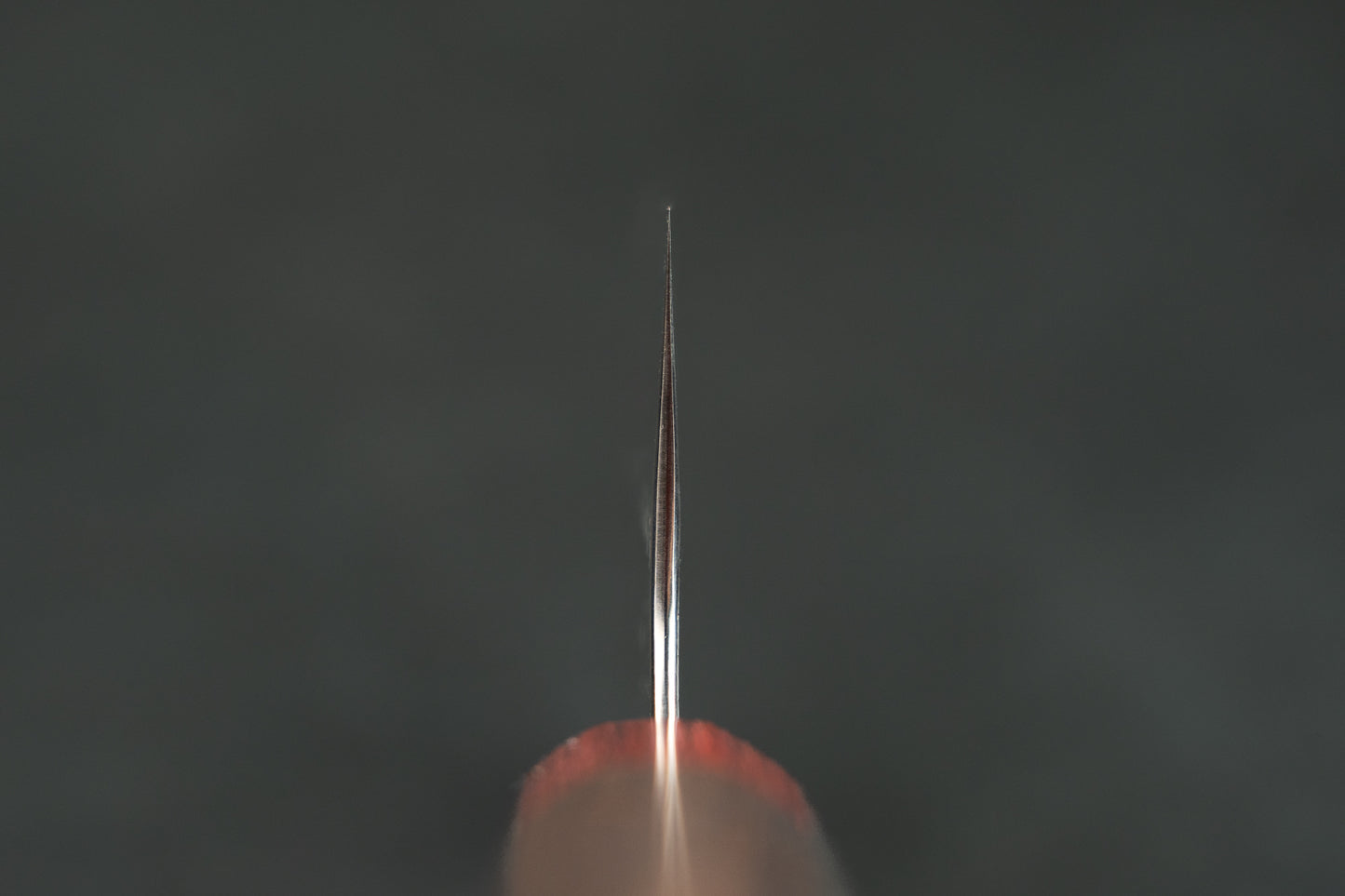

About the Shape - Under utilized in the western kitchen, the nakiri’s flat blade is meant for the push/pull chopping of vegetables. Since the entire flat edge of the knife ktouches the cutting board at once, you wont be turning the vegetable into an 'accordion', still connected like a paper doll after you've cut them. The added weight of the blade allow it to fall through food more easily while you chop, so the knife does more of the work for you! Masakage nakiris are made taller than the average nakiri so they last longer and work better for folks with large hands.

| Shape | |

|---|---|

| Blade Length | |

| Blade Height | |

| Blade Thickness Above Heel | |

| Weight | |

| Steel Type | |

| Rockwell Hardness | 62–63 |

| Blacksmith | |

| Edge/Bevel | |

| Handle | |

| Made in |

A note about measurements: Handmade Japanese knives can vary in their dimensions, so these measurements are only an example.

Knife Care

Knife Care

Shipping and Returns

Shipping and Returns

We aim to ship your order within 1 business day at Knifewear, if there is a hold up, we'll aim to let you know and give you a timeline.

We offer $3 shipping on orders over $100* anywhere in Canada and $200* to customers in the USA. We ship worldwide, and offer up to the minute rates from our shipping partner DHL.

*Konro Grills and some other larger items are excluded from the free shipping offer.

How do I make a return on an online order?

No worries, we've got you sorted. Head over to https://knifewear.com/returns and follow the prompts.

Can I pick up my order Curbside / At the store?

Absolutely, as long as all the items you are looking for are in stock at the location you want to pickup from, you'll be able to select that at the checkout. If one or more items aren't at your preferred location we are happy to ship it to you.

Recently Viewed

-

Yoshimi Kato SG2 Minamo Nakiri 165mm

Regular price $480.00 CADRegular priceUnit price per